When Inter Ordnance (aka. I.O. Inc.) moved from North Carolina to Florida two years ago, the company’s stated goal was to seek out better talent in order to improve the quality of their builds. Even so, many AK enthusiasts who feel burned by the company’s past offerings have been reluctant (or downright unwilling) to believe the company’s claims. Indeed, the animosity against I.O. in online forums is so intense that most discussions of their AKs devolve into arguments and rants. In order to give I.O. a fair shake, Atlantic Firearms sent out an open invitation for reviewers to check out one of I.O.’s standard AKM247 rifles. As an AK enthusiast and collector, I had to take the bait.

About the Rifle

Since the AKM is probably the most prolific rifle ever conceived, I will save the history lesson that I would normally dive into at this point in a review. Suffice it to say that the design is a product of the late 1950s, is an evolution of Kalashnikov’s AK-47, and there are millions of AKMs from multiple countries in worldwide circulation. The AKM 247 is I.O.’s attempt to tap into this design and legacy with a wholly American made rifle.

As an AKM-based firearm, the AKM247 is chambered in 7.62x39mm and is built around a stamped steel receiver. The roughly 16-inch barrel is capped with a standard AKM slanted muzzle brake and the gas block is the classic 45-degree style with a functional bayonet lug. The AKM247’s rear sight leaf is notched like all other tangent rear sights and is graduated in 100 meter increments all the way out to an optimistic 1000 meters. While the AKM247 is compatible with all AK magazines, it ships with two polymer, US-made 30-round magazines. In a departure from a military AKM, the magazine release on the AKM247 has an extended paddle and the safety is notched in order to lock the bolt carrier near its rearmost position. Lastly, the rifle comes with a cheap cleaning kit.

Finish

Most of the steel parts on the AKM247 exhibit a flat gray parkerized (or phosphated) finish. I know some shooters will prefer a nicer painted or blued treatment on their rifles, but in this price range such luxuries cannot be expected. Parkerization offers better corrosion resistance than bluing and also happens to provide an excellent base coat for people who are interested in painting the rifle after purchase. Typically, most modern military AKs employ some sort of phosphate treatment under a painted finish. I have had great success using appliance epoxy over the top of similar finishes and the end product looks very similar to a Russian paint job, but is actually quite a bit more durable. In light of this fact, I have no problem with the phosphating on the AKM247.

Nitride barrel with phosphated parts. Note the odd use of roll pins for the gas block and front site. I.O. tells me they are moving away from these.

The barrel on the AKM247 has undergone nitride treatment for added strength and corrosion resistance. Many AK purists balk at nitriding as incorrect or not true to original specifications. While they are correct, nitride treated barrels can actually be excellent options for budget-minded builders and shooters. Treated barrels often approach their cold hammer forged (CHF) counterparts in overall hardness while offering similar corrosion resistance to chrome lined options. Since nitriding is a penetrating treatment done to the steel of the barrel, it does not require the bore to be cut oversize, as is the case with chrome lining. There is also no risk of flaking, a flaw that sometimes manifests in chrome lined barrels. While I will wait until the Range Report to address the accuracy of the AKM247, I can say that the nitride barrel’s performance impressed me enough to consider similar options in future builds.

Furniture

At my request, Atlantic Firearms provided me with the AKM247-C version of Inter Ordnance’s rifle. The “C” suffix denotes “classic”, meaning this rifle has a wood stock and similarly laminated handguards. Made with Canadian birch, I must say that it is some of the best made non-Russian laminate I have seen. The grain is not quite as nice as true Russian examples, but the laminated layers do possess a similar “chameleon”, or color shifting appearance.

The overall shape of the furniture is also reasonably close to original laminate. The stock’s comb approximates the typical Izhmash cut and the upper handguard is made out of thinly cut veneer that has been wrapped into shape. While the bottom of the lower handguard does not feature a drain hole, this area is appropriately cross-laminated (the lower handguard is constructed of three separate laminate sections that have been glued together). The palm swells on the lower handguard are not perfectly accurate for an AKM and feel more like those found on AK-74s. Unlike most AKM variants, the stock has a ribbed butt plate that features no trapdoor for storage, so the five or six people that actually keep a cleaning kit in there might be disappointed. The whole set appears to be finished in a sprayed-on lacquer.

After all this praise, it is disappointing that I.O. insisted on slapping a huge “Made in the USA” sticker on the left side of the stock. Removing this decal and the sticky residue it left behind practically necessitates refinishing the entire furniture set. I could not help but roll my eyes in disgust as I carefully, but rigorously scraped at the mess left behind by this gaudy sticker. Even with rubbing alcohol, I could not completely remove the tacky substance. Frankly, when the box, manual, and receiver all say “Made in the USA”, slapping it on the stock is just flat out overkill and a bit tacky (pun intended).

The pistol grip is the only real detractor from this otherwise superb furniture set. The grip looks and feels like the awkward love-child of an affair between a Galil and an AK. I prefer traditional AK grips and this one does not fit my hands well at all.

Trigger

Shooters who have handled a semi-automatic AK or two before would immediately recognize the AKM247’s trigger. While not officially Tapco branded, the I.O. trigger is very similar in both feel and appearance to the popular G2. As a result, the pull is exceptionally light and crisp. At around 3.5 pounds according to my Lyman trigger pull gauge, The AKM247’s trigger is right around what I would consider ideal for a semi-automatic defensive rifle.

Magazines

Typically, I would not spend much time talking about the magazines that come with an AR or AK variant. With so many great options on the market, most of us already own a pile of our favorites and use them with all compatible rifles. However in this case, I have chosen to make an exception. As a result of its features and price, the AKM247 is positioned as an entry level AKM clone. Because of this, I expect most people who are interested in the AKM247 are unlikely to have a deep stash of AK magazines ready for use with the rifle like some of us collectors might.

The rifle has a phosphate finish and an optics rail on the side. Note the magazine, which outwardly resembles a Bulgarian “waffle mag”.

The included magazines outwardly resemble Bulgarian “waffle mags”, but are closer matches for the waffle pattern Pro-Mag offerings. I cannot say for sure that Pro-Mag is the OEM for the I.O. parts, but I strongly suspect they may be. Two magazines are included with the rifle and each holds 30 rounds, but one of the parts I received was improperly assembled and only held 26 rounds out of the box. The feed lips and locking lugs on the I.O. magazines are not steel reinforced, so shooters who plan to run the rifle hard may want to upgrade to surplus steel magazines to mitigate the risk of breakage. For casual range use and plinking however, they should fit the bill. When locked into the rifle, the I.O. magazines exhibit no wobble, but they can be somewhat challenging to insert when new. I have also found that the bolt and carrier tend to drag on the feed lips of these magazines, whereas others do not.

I have had very good luck with using surplus and other aftermarket magazines in the AKM247. My steel Russian and Egyptian magazines fit perfectly, as do commercial Bulgarian 40-round polymer magazines and Magpul P-MAGs. Of the above, the P-MAGs are the only ones that are slightly loose when inserted. Brief testing also revealed that all of these options fed the AKM 247 reliably in controlled conditions. I did not carry out an extensive torture test of the I.O. magazines, nor did I validate that all other magazines would continue to work with the AKM247 when exposed to harsh conditions.

Build Quality

Without question, the top questions surrounding these new I.O. AKs relate to their parts and build quality. Most who read this review will be familiar with I.O.’s questionable past and well-earned bad reputation. I.O. claims to have turned a corner, but most enthusiasts are not buying it. My experience with the AKM247 has been a mixed bag, but in general the rifle works as expected.

To start, the sights on my example are incredibly straight and required some very minimal windage adjustment to zero. The rifle as a whole is tight and had no rattle (aside from the sling swivel) out of the box. The cast parts are surprisingly well finished.

In terms of materials used, the barrel is 4140 steel that has been nitride treated for corrosion resistance and hardness that approaches cold hammer forging. According to I.O COO Ramzi Kheireddine, the cast parts (front sight base, gas block, rear sight base and leaf, front trunnion, bolt carrier, and rear trunnion) are all made of 4140 steel as well. The stamped receiver is fully heat treated and the bolt appears to be nicely machined and of high quality.

Note the dimpled receiver. This image also shows the cast trunnion. The shadows around the rivets are caused by excess oil.

On a less positive note, I did experience a crippling malfunction early in my first range session with the AKM247. Feeling that the rifle was overgassed and a bit harsh on the shoulder, I went ahead and pulled the recoil buffer from the gun. In my opinion, a properly built AK has no need for such additions. Unfortunately, removal of this part led to an almost immediate show-stopping malfunction.

The photos illustrate the cause of the failure. Without the buffer, the bolt carrier was able to travel back in the receiver far enough to jump off the welded internal rails. While some military AKMs will jam like this on occasion, it is fairly rare. Unlike such “milspec” rifles, the AKM247’s bolt carrier does not have a chamfered leading edge to help prevent this jam. After discussing this issue with I.O.’s Ramzi Kheireddine, it appears the company will be using chamfered carriers moving forward (see update at the end of this review).

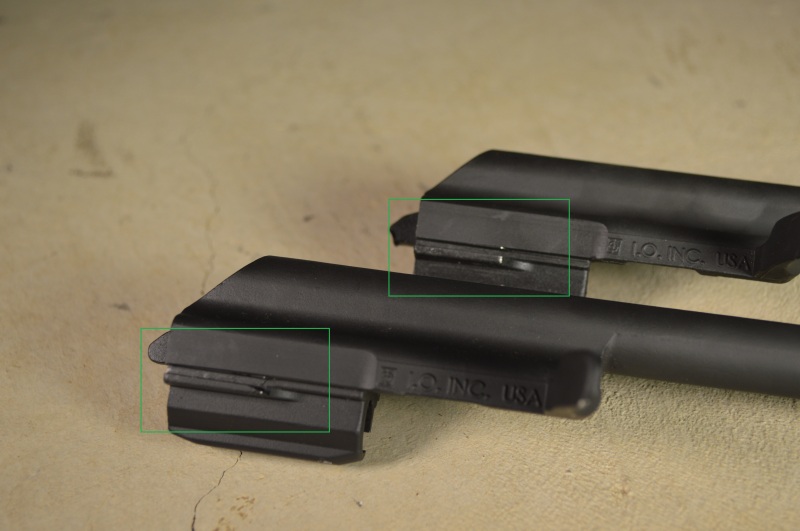

Note the geometry differences between the AKM247 carrier (top) and Saiga carrier (bottom). The highlighted chamfer can help prevent malfunctions.

On a properly built AKM, the receiver should be dimpled into the countersunk lower hole of the front trunnion and a swell-neck rivet should be used for additional strength. Likewise, both rear trunnion rivets should be swell-neck style and installed in dimpled holes. In my initial assessment, I concluded that the AKM247 did not use the proper rivets or dimpling in these areas. This would have meant that the security of both trunnions relied entirely on the shear strength of the rivets. On a rifle that is already noticeably overgassed, these omissions worried me. According to Ramzi, my determination was not correct. The trunnion rivets are all swell neck fasteners that have been crushed in dimpled/countersunk holes. However, it appears the company is countersinking all the holes on the front trunnion. This is a departure from traditional AKM trunnions that only have countersunk lower holes. It also appears that the receiver has not been fully dimpled underneath the swell neck rivets. Notice how the front two rivets have a lip around their heads. This looks to me like the swell neck is actually mushrooming out of the hole during compression.

According to I.O., these rivets are properly installed into countersunk trunnion holes. If so, this is likely the least obvious example of such work. Usually, receivers appear “pinched” around these rivets.

Lastly, the front trunnion is a cast part that is then riveted to the receiver subsequent to barrel installation. Outside of the bolt and barrel, the front trunnion is probably the part exposed to the greatest pressure when the rifle is fired. This is a part that has never (to my knowledge) been made from castings on military rifles and I am concerned that the cast trunnion might lack the strength of traditional milled parts. Furthermore, it is not ideal to rivet the trunnion after barrel installation. This order of operations leads to the barrel being used as a bucking bar for the rivets. While this will not damage the barrel, it makes it impossible to determine if the rivets have crushed properly.

Range Report

The first thing I noticed when shooting the AKM247 was that the rifle is quite clearly overgassed. Compared to my Saiga, the AKM247 is considerably less pleasant to shoot. I will not go so far as to say that the rifle feels like a .308, but I.O. has verified that the gas port is drilled at the high end of spec, likely close to some of the Chinese rifles out there. According to the company, the rationale behind this decision was to increase the rifle’s reliability with multiple types of ammunition because early adopters had complained about sluggish cycling. Frankly, I feel that their issues were probably caused by the included magazines and the buffer-shortened recoil stroke. Still, I.O. has asserted that they will be sticking with the large gas port.

Once I got past the surprisingly stout recoil impulse, I was surprised to see that the rifle is very accurate for a standard AKM build. The sights needed almost no adjustment out of the box and I was easily able to crank out 2 MOA groupings at 25 yards. My eyes simply aren’t good enough to stretch out my groupings to 100 yards, but suffice it to say that I shot the AKM247 better than my Saiga, at least until my shoulder got tired. I give the nitride barrel and excellent trigger credit for this.

Over the course of 300 rounds and not counting the bolt carrier malfunction, I experienced two additional failures with the AKM247. The first came right around the 150 round mark and was a double feed from one of my commercial Bulgarian 40-round magazines. I am inclined to blame that issue on the cheap magazine and not the rifle. The second was a failure to extract that cropped up after around 225 consecutive rounds fired. I was able to clear this malfunction by removing the magazine and charging the rifle.

This target has around 200 rounds through it. This target was used while I was attempting to heat the gun up with steady fire (around 1 round per second). Distance was approximately 30 yards, but I was not looking for much in the way of accuracy during this test.

Conclusion

The AKM247 is a difficult rifle to assess. Despite some of the issues I have encountered with this rifle, I do feel that I.O. has improved their product compared to previous offerings. At the same time, there are still several changes that need to be made to bring the rifle to the same quality level as the European AKs or kit builds that are plentiful today. I know that Ramzi and others at I.O. love the AK platform and the company feels that US manufacturers can build every bit as nice a rifle as foreign competitors, so I am hopeful that the necessary improvements will be made in time. However at the same time, I.O. has taken a stance that they will not make certain tweaks that I feel are important, including shrinking the gas port and removing the recoil buffer. This is an issue that could affect the longevity of the rifle and while it may never fail in my lifetime, I buy firearms with the intent to pass them down to my future children and grandchildren so I expect them to last well beyond me.

With increasing uncertainty surrounding AK imports, it is nice to see US companies trying to take on full production stateside. But in the current environment, we have to consider that a Romanian WASR commands only a small premium over the AKM247 and offers (arguably) superior, military spec build quality. With this in mind, I find it difficult to recommend the AKM247 over rival options at this time.

Update (6/14/15)

Last week, I received the modified bolt carrier from Inter Ordnance. This part has chamfers on each side where the carrier engages the rails of the receiver. Fortunately, my testing has shown this new carrier to be much better than the original part. After the swap, the rifle functions perfectly without the recoil buffer and I really appreciate the longer recoil stroke. I also found it interesting that using the new carrier without the recoil buffer almost entirely eliminated the sluggishness I previously experienced while charging the rifle.

The carrier at the bottom of the photo is the new example. Note the differences in the highlighted areas.

The carrier at the bottom of the photo is the new example. Note the differences in the highlighted areas.

Even with the changes, I still would lean towards other options at this price point. The AKM247’s large gas port still makes this rifle less pleasant to shoot than most European AKM variants, even with the recoil buffer removed. I know I.O. has stated that the larger port has been drilled to ensure reliability and reduce stickiness during cycling. My testing has found that these issues are better addressed by swapping for a correctly machined carrier and removing the recoil buffer to allow for a full recoil stroke. If I.O. were to reduce the gas port size, swap the front trunnion for a milled part, tweak their riveting process for the front trunnion, and drop the MSRP of the AKM247 to around $400, I might be more inclined to recommend the rifle to shooters looking for a bargain AK. As it stands, there are simply too many other solid choices in the AKM247’s price range that offer more appealing features and more tested build processes.